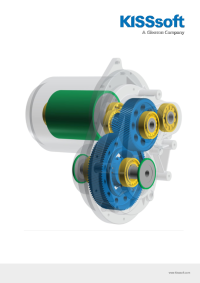

Gears

The gear calculation covers all common types: cylindrical, bevel, worm, crossed helical, hypoid, and face gears. In addition to calculations based on standards ISO, DIN, AGMA, VDI, etc., numerous sizing and optimization tools are offered, as well as methods that go beyond the standards.

Specifications

Shafts and Bearings

The shaft and bearing calculation is fully integrated in KISSsoft®. Among other things, shaft strengths and rating life of bearings are calculated optionally taking into account internal geometry (ISO TS 16281). The calculation can include several coaxial shafts and their connecting bearings. Torsion and bending-critical eigenfrequencies of the shafts are determined.

Specifications

Shaft-Hub Connections

Specifications

Bolts

The calculation of bolted joints in KISSsoft enables verification in addition to VDI 2230 Sheet 1 and proof for bolts with FEM results as described in VDI 2230 Sheet 2. Supplementary calculation methods as used in the industry, in addition to VDI 2230 have been implemented. In addition to the report, the distortion diagram, the assembly preload, and the bolt geometry are displayed in graphics.

Specifications

Springs

The most common spring types can be calculated and verified. In order to find a suitable spring for a given load, there are numerous sizing options for individual parameters. A database containing the most common spring materials and wire diameters is provided in KISSsoft®. The tolerance standards are also contained in the KISSsoft® database. For illustration, the spring characteristic curve and (if available) the Goodman diagram are shown.

Specifications

Belts and Chain Drives

KISSsoft® offers a calculation of V-belts and toothed belts according to available standards and calculation guidelines from the manufacturers. The chain calculation includes the chain type according to DIN ISO 606 and a calculation basis according to DIN ISO 10823. These calculation modules offer helpful sizing functions for the belt length, center distance, necessary width, or number of belts.

Specifications

Tutorials

Our tutorials offer step-by-step instructions for specific calculation tasks. We recommend these documents for a good introduction in the application of KISSsoft.